Remarks MWR for plate bending, code clean up. Code can be found here Plate buckling research. Try solving buckling equation using MWR. (Result: Not how it works. So I need to try something else.) Details Dec 28, 2020 (Monday) MWR for plate bending, code clean up. Code can...

Remarks Solving trial function calculation problem. Visually reasonable results achieved with reasonable / faster calculation time. (The problem is when changing symbolic expression to double numerical value, numbers are cut to 17 digits, which is not accurate enough and cause more trouble. The...

Remarks Calculation speed increased 50% for calculating trial functions. Automatically determine minimum polynomial order. Calculation speed increased >90% during calculation of residual integral. The way to do this is by implementing a new integration method. The new method and th...

Paper Paper milestone write up: The link: https://www.overleaf.com/read/zkyzhqtbyvvk It's very welcome to have your comments and feedbacks. Thoughts about validation: Design parameters: Figure out a easy way to measure the design parameters of the physical blimps, the parameters space...

Previously, I finished the feature matching and id assignment in the SLAM frontend. Last week, I combine the result with the preintegrated IMU data to formulate an optimization problem. Initial values I initialize the landmark position by triangulate two frames. The selection of these two points...

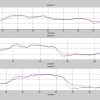

Purpose This blog is to pose optimization results of the IMU erro function in Tsangkai's project. In this test, I try to use simulation data to test the "imu_error" function to examine whether the code is right or not to perform optimization function. Input and output There are two tests. ...

okvis is a visual odometry. Therefore, the feature matching only occurs within short time window, and the feature matching that enables loop closure is not provided. The following is the overview as well as the result of the feature matching that I implemented. Keyframe selection This part relie...

This past week, I focused on improving upon the altitude filtering algorithms I had tested previously for the blimps on FORAY. The previous two algorithms I had implemented (both in arduino and in MATLAB) were a moving average filter and an exponential filter (both first-order filters). Both intro...

After surveying several SLAM and visual odometry implementation, I decided to work on okvis with monocular camera setting. I will run an nonlinear optimization on the output of the visual odometry system, which can be regarded as global bundle adjustment with IMU constraints. The output of visua...

Structure: 4 motors configuration (attackers) 3 motors configuration (defenders) Special case with the strong thrust Electronic system There are several components in our electrical system: Control board: NodeMCU-esp8266 Motor driver: tb6612-fng Motor : 8.5 * 20mm Propeller...