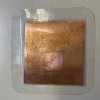

Last week, we got new machines for battery fabrication. Now we can created more delicate batteries, as shown in the attached figure. The voltage is about 1 V. However, the current methods can not guarantee the close contact between electrodes and filter paper, which caused extremely lagger resistanc...

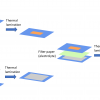

The basic fabrication porocess of the proposed printable battery is shown as the figure. We need to firstly combine the electrodes (Zinc or copper file with pouch sheet), which is completed by thermal lamination, resulting in composite electrodes. It is wotrhting noting that we need to cut a hole on...

How to customize batteries according to your requirements? It is very challenging to design a battery to satisfy specific loading. For example, you may need to have a battery that can outup certain current when connected to an electric-driven actuator with a certain resistance. Similarly, for our pr...

The basic fabrication of a printable battery includes electode formation and battery packaging. Here I use a Li-ion battery as an example. The first step is the electode fabrication, which includes slurry preparation, coating, cutting of electrode, electrode calendaring, electrode slitting, and t...

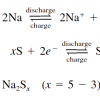

For our printable robots, we are planning to integrate printed battery as on-baord power. Currently, we choose Na-ion battery given the relative high voltage, low resistance, low cost, and high drain current, etc. There are two main types of Na-ion battery, i.e. sodium/sulfur battery and sodium/meta...

- «

- »