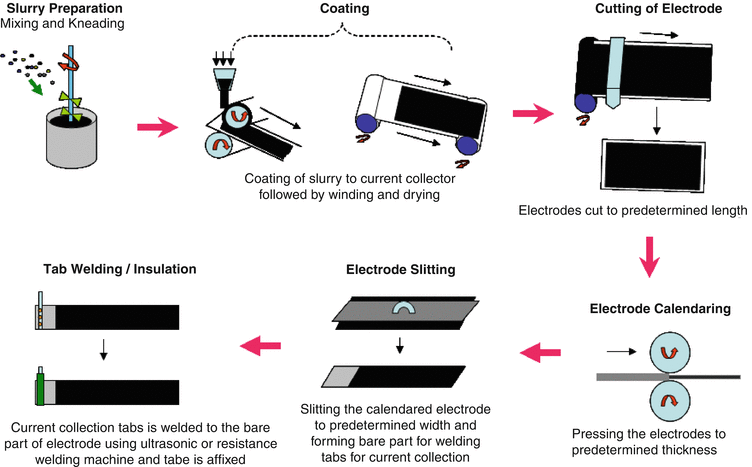

The basic fabrication of a printable battery includes electode formation and battery packaging. Here I use a Li-ion battery as an example.

The first step is the electode fabrication, which includes slurry preparation, coating, cutting of electrode, electrode calendaring, electrode slitting, and tab weling/insulation, as shown in following figure.

[1]

[1]

After finishing the preparation of electrodes, a battery packaging process is required to assemble the positive electrode, seperator, electrolyte, negtive electrode, and case. This packaging process usually utilize heat press.

For more fundamental mechanism of Li-ion battery, please check this link out.