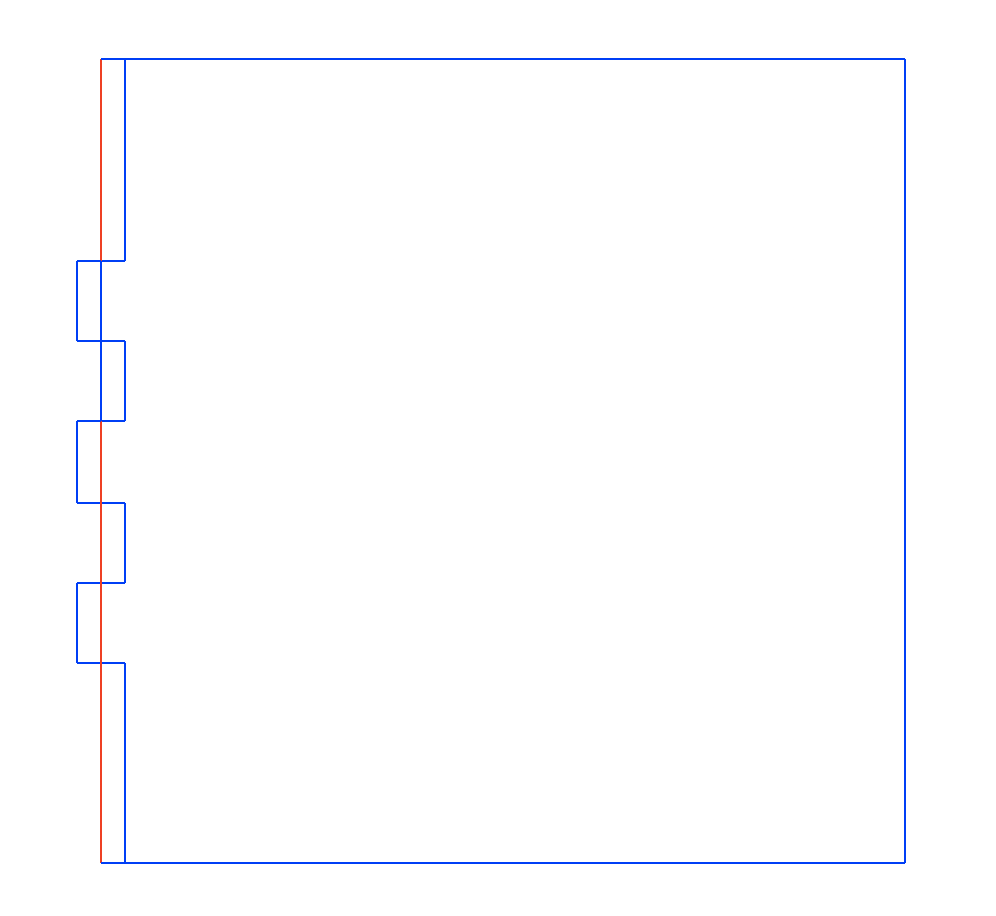

Finally, the finger joints can be appropriately added into connection between selected subcomponents. The way we achieved this goal is to call specific arguments in make_output() function without adjusting our RoCo system.

c.make_output(tabFace=maleFingerJoint,tabDecoration=maleFingerJointDecoration,slotFace=femaleFingerJoint, slotDecoration=femaleFingerJointDecoration)__

In this way, the RoCo system can keep universal and versatial. The function can automatically decide how many small "fingers" we need to be added into the edge according to its length. Also, special pattern was designed to allow the users to construct their furniture with three edges in the corner. In order to make the manufacture process easier, I plan to revise my code a little bit to allow the system can automatically convert the design into the format that can be used in our laser cutter. And also there are some bugs needed to be fixed to achieve our goal.

On the other hand, two different methods were tried to fix the contact problem. It didn't work well yet. I will continue to come up with new ideas. One of them is to use conductive grease. Let's hope this works!