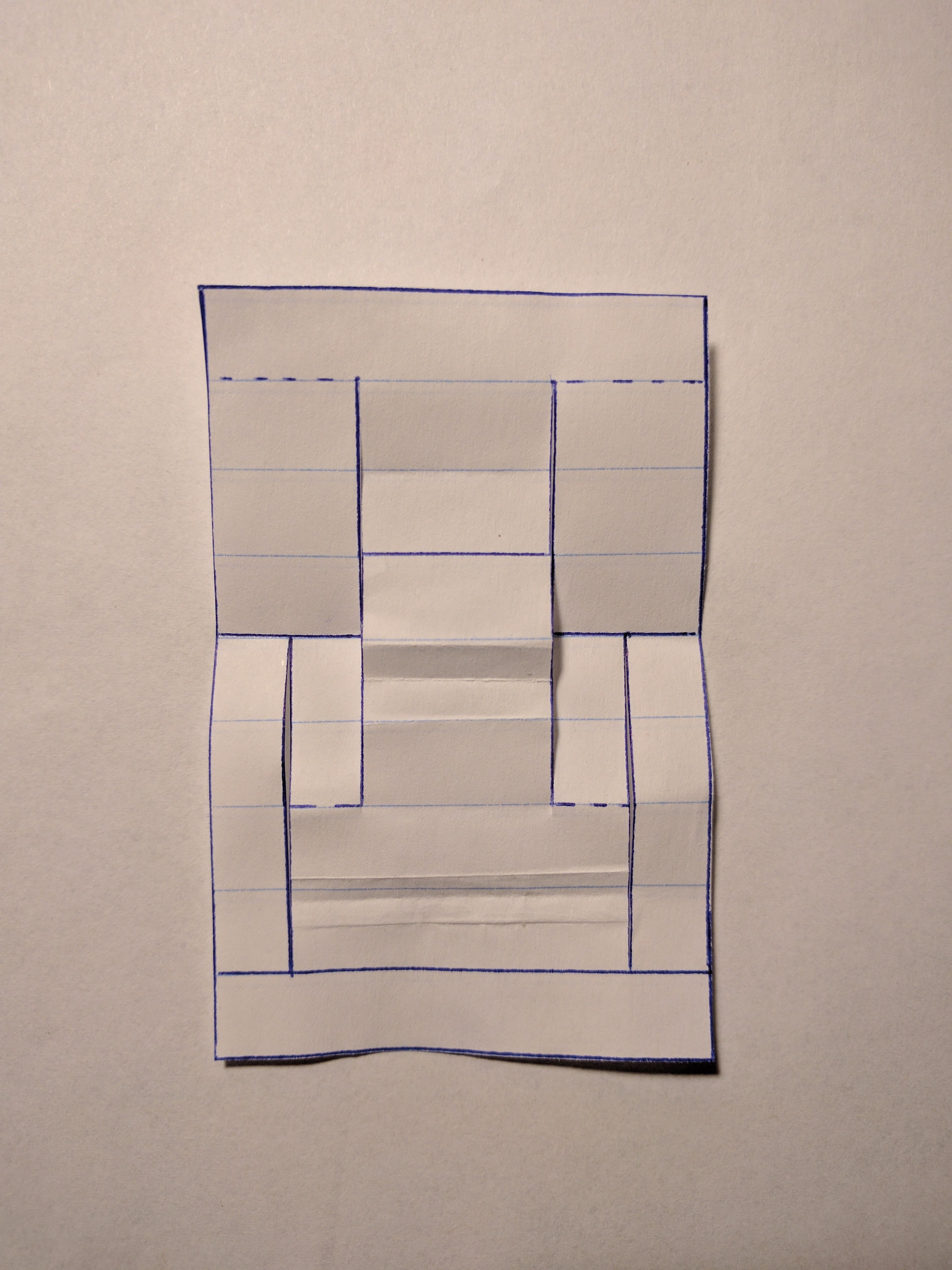

Following on from identifying the Peaucellier-Lipkin linkage as a potential solution to the straight line mechanism problem, the system was created using paper. However, issues became immediately apparent and are listed below:

• Rigidity: The paper does not have enough rigidity to handle the forces when the system is actuated. As a result, bending occurs and the system does not function as expected. The original system was designed and created under the assumption of very limited bar deformation and so this alternative characteristic needs to be accounted for

• There is a tradeoff between rigidity and malleability as the thickness of the paper increases. Rigidity is highly desirable as was mentioned in the above point but malleability is also required in order to shorten the lengths of some parts of the paper.

• The linkages tend to want to rotate about the nearest fold as opposed to transferring the force to the next joint etc.

• The paper not only bends under the actuation force but it also warps as a whole unit. This is because one half of the system is a mountain joint and the other half is valley joint in order to create a symmetry about the horizontal plan. As a result, the paper warps and deforms due to the unequal forces and lack of symmetry from a bird’s eye view.

• Lastly creating the two achoring points is a significant challenge since it requires an arm or reach over structure of some kind.