1. Here is the intermedium results: plane stress of a CFFF rectangle plate, with uniaxial load

- The magnitude is the same, results are close (at least visually).

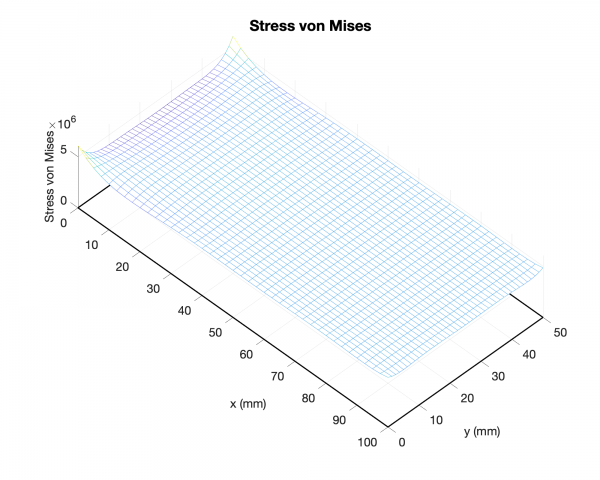

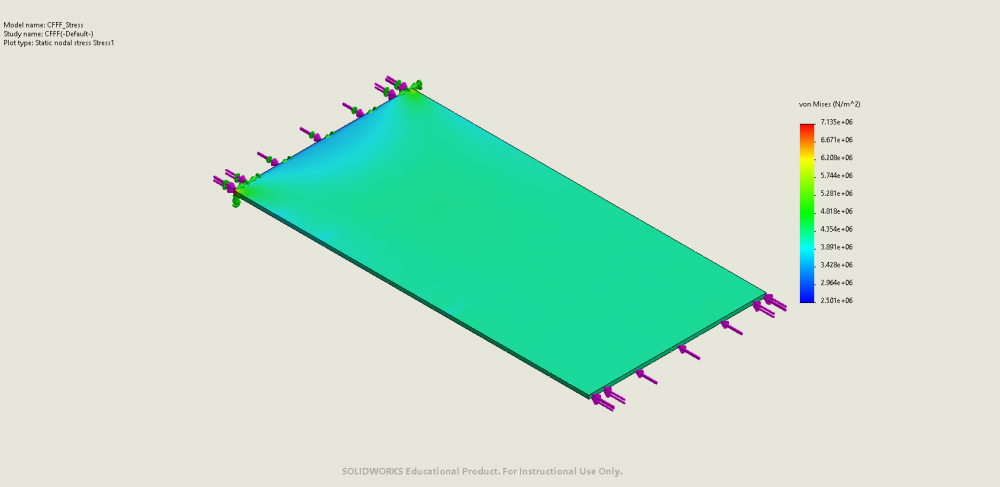

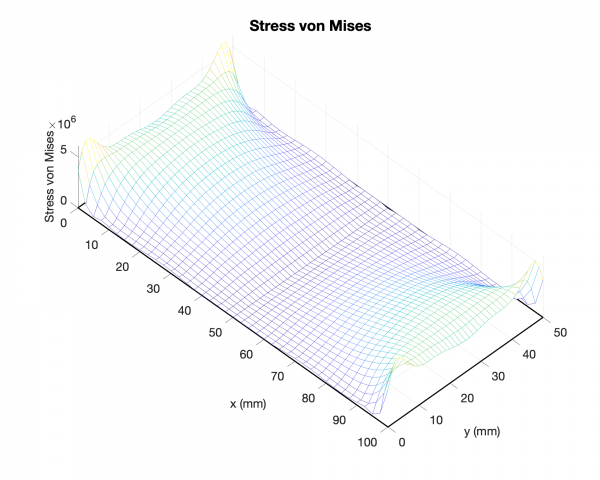

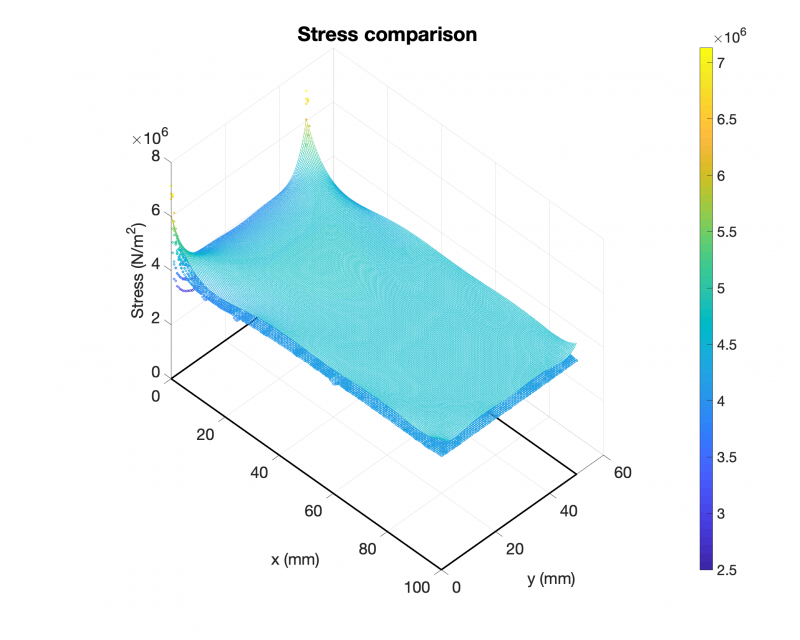

Stress

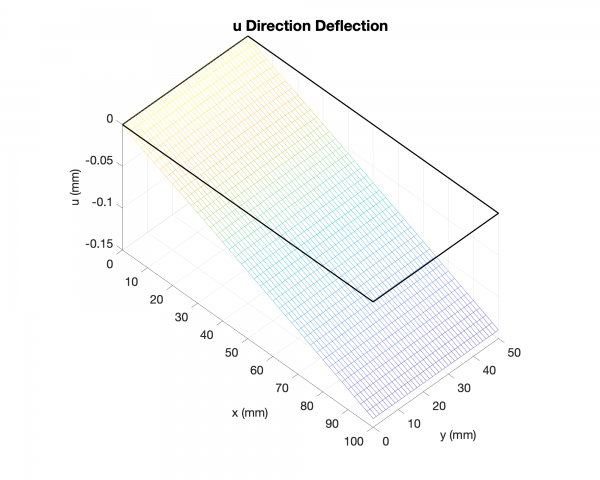

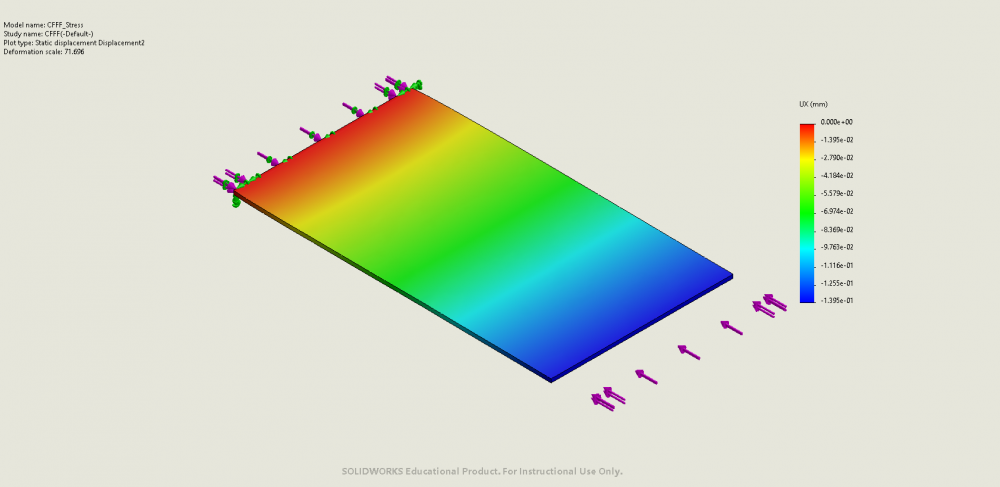

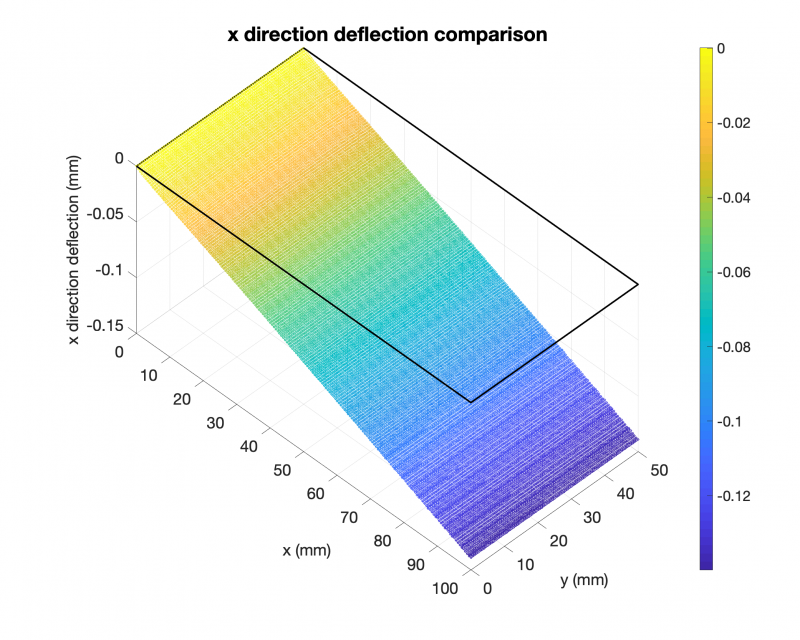

u direction displacement

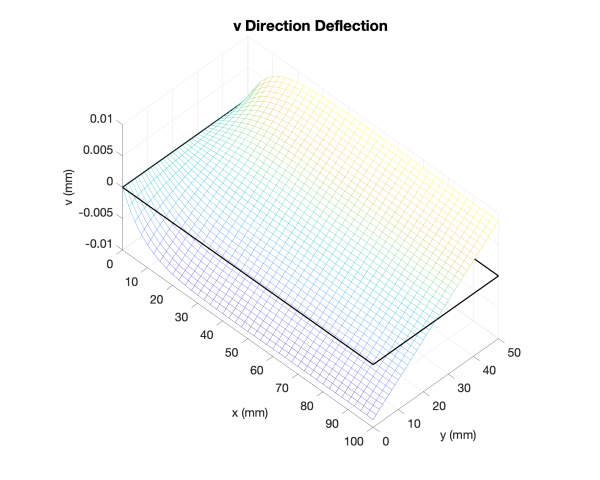

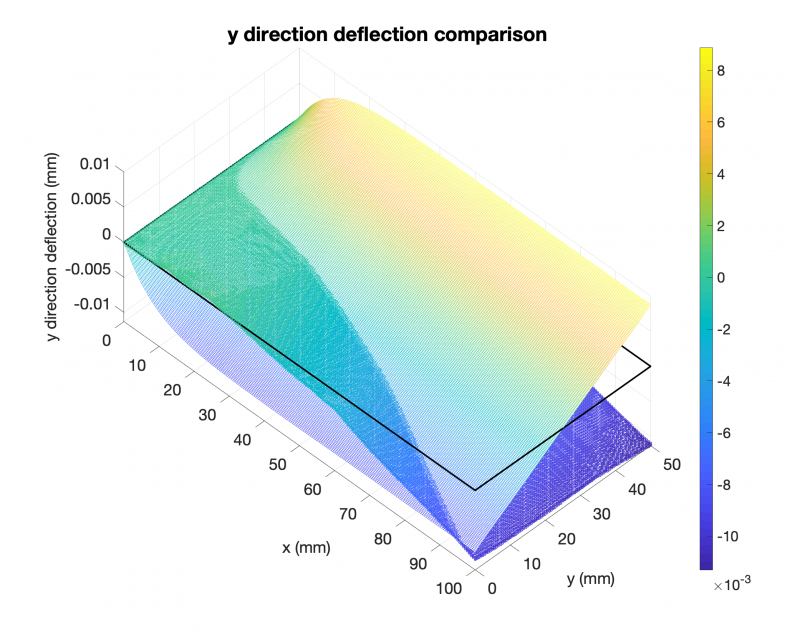

v direction displacement (results do not match well, but this is not the direction of interest and effect is relatively small)

A few things to note:

-

Load unit: N/m

-

Can not fully restrain the plate. e.g. CCCC and SSSS does not give result, since there is no displacement allowed on edges, aka internal.

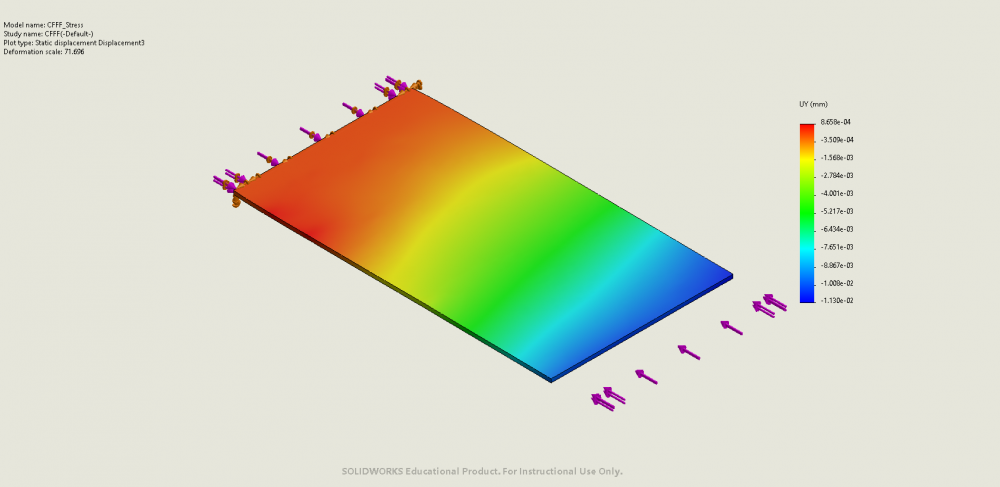

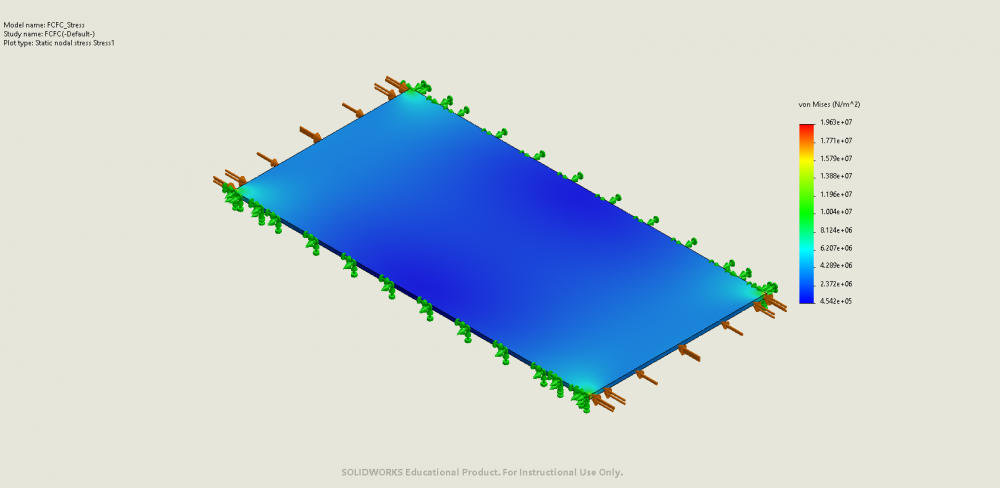

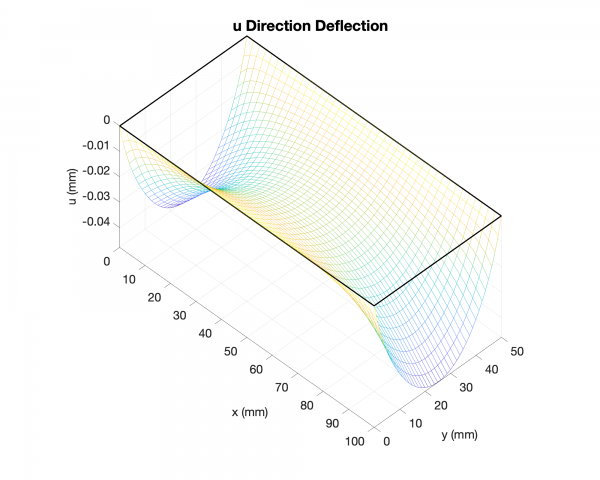

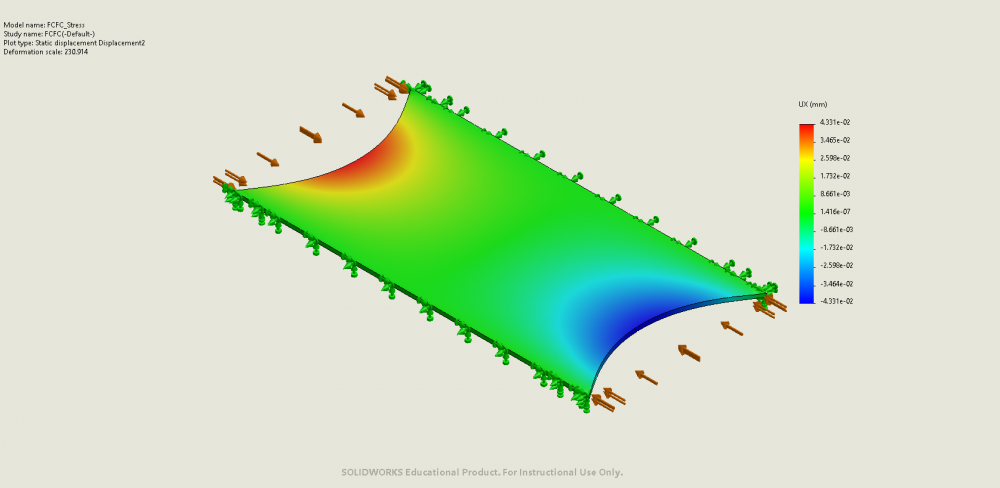

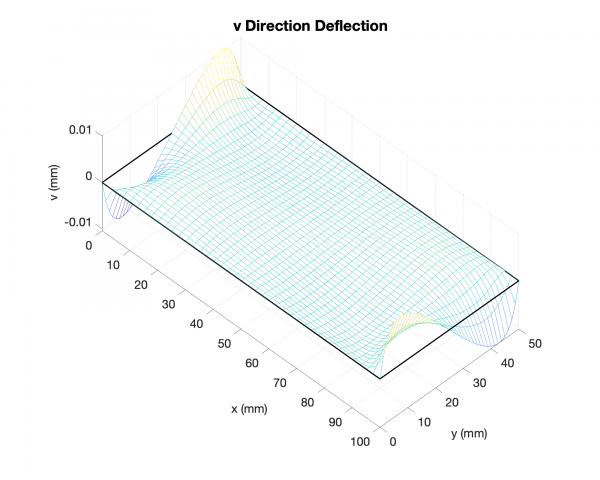

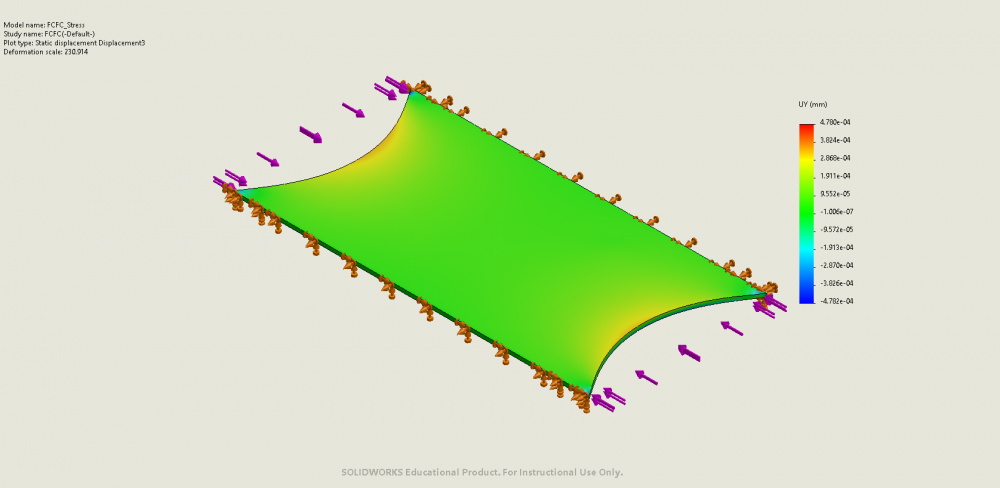

2. Here is the intermedium results: plane stress of a FCFC rectangle plate, with uniaxial load

- The magnitude is the same, results are close (at least visually).

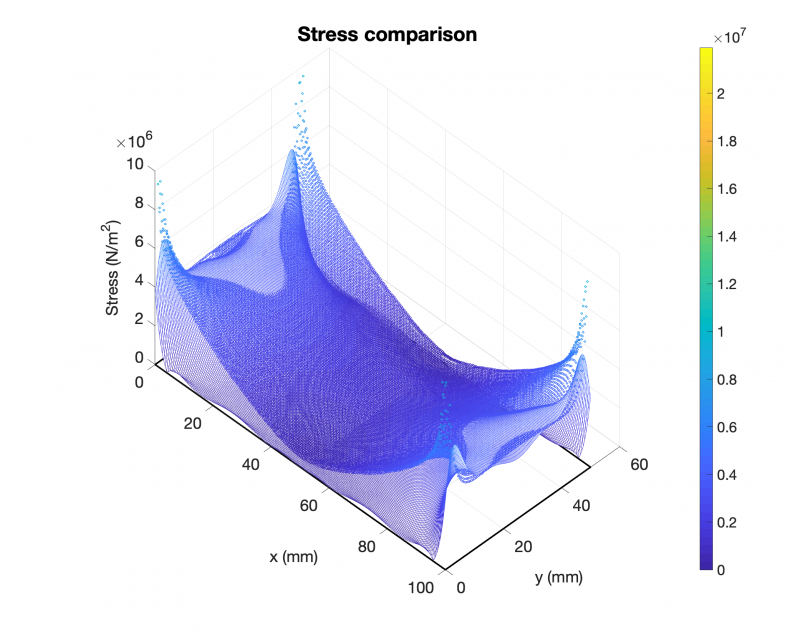

Stress

u direction displacement

v direction displacement (results do not match well, but this is not the direction of interest and effect is relatively small)

Things to do

- Distributions in FEA are not easy to observe. Working on finding a way to either get the data saved locally, or plot in another way in FEA. [DONE]

- All edges clamped or simply-supported can not be analyzed in our design tool. By instinct, they are not supposed to work, since if all edges are clamped or supported, edges will not move under force and no buckling should happen. But there exists analytical solutions to those cases, which is weird. I will spend some time figuring out if i missed anything.

Instructions on how to get FEA data saved in .csv file, so that we can better compare results.

Steps in Solidworks Simulation:

-

(1) To find / log coordinates:

-

(1.1) Simulation (in toolbar) --> Result Tools --> Probe

-

(1.2) On selected entities --> Node --> Results (select all surfaces, or else) --> Update

-

(1.3) Results should display --> Save as csv

-

(2) To find / log results, e.g. displacement, stress, strain:

-

(2.1) Simulation (in toolbar) --> List Results --> Displacement (or stress, etc)

-

(2.2) Pick what you want to list in quantity and component --> (in Advanced Options) choose Range (default to all nodes) --> List Set selection

-

(2.3) Save

Results comparison for CFFF case

Stress comparison

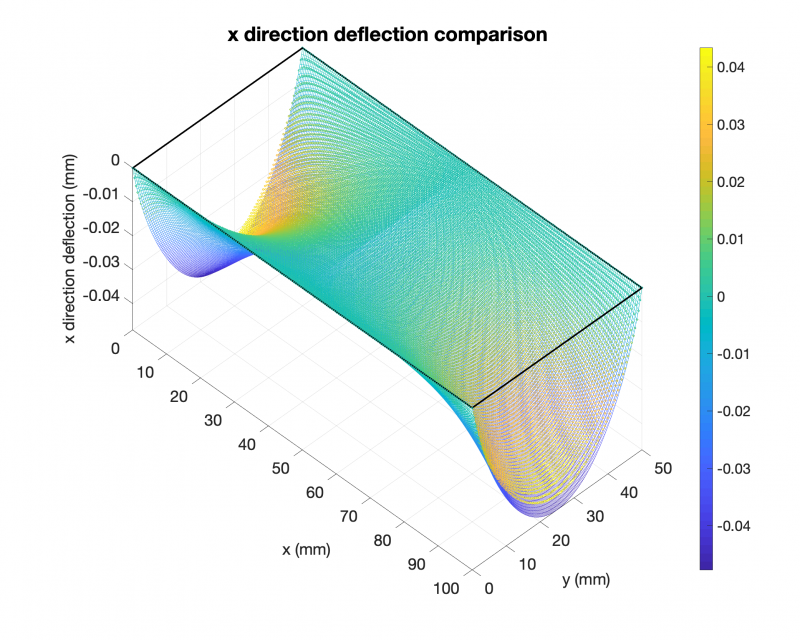

x direction deflection comparison

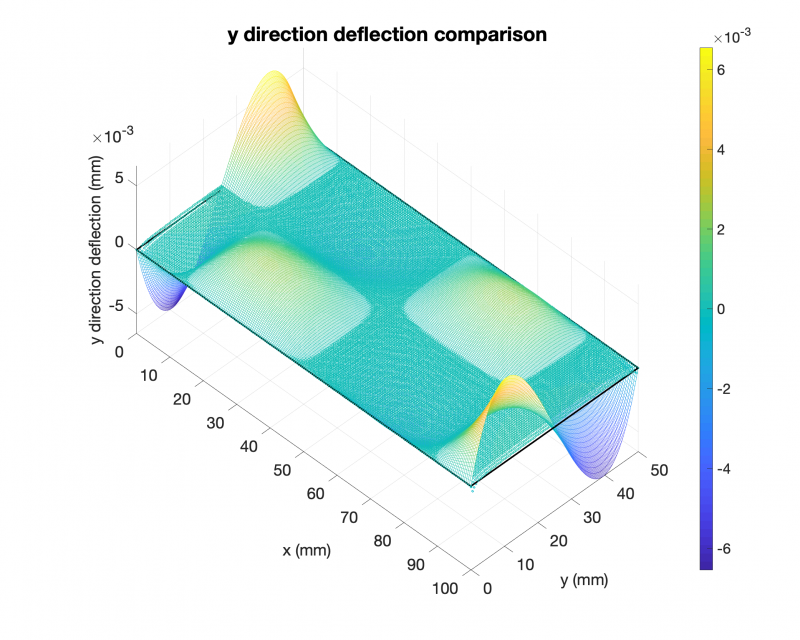

y direction deflection comparison

Results comparison for FCFC_ case

Stress comparison

x direction deflection comparison

y direction deflection comparison

Summary

- Stress distribution matches well enough. Results are close, which means a lot.

- x direction deflection matched very nicely.

- y direction deflection is off a lot, but the magnitude is relative small compared with x direction, which have minimum effect in final result (stress). Also this could be caused by the direction of loads, which is along x axis.

- Error to be calculated and evaluated.